LGZT Compact Wheel Loader: Boosting Productivity in Southeast Asia and South Africa – A Success Story from Indonesia

In the booming construction and agricultural areas of Southeast Asia and South Africa, the demand for efficient, durable and cost-effective heavy equipment has never been greater. Among the various equipment supporting these industries, the small wheel loader stands out as a versatile workhorse, capable of handling a wide range of tasks, from material loading and unloading to site preparation. LGZT, a leading construction equipment manufacturer with a global presence, is at the forefront of producing high-quality small wheel loaders tailored to the unique needs of the Southeast Asian and South African markets. This case study focuses on PT. Bumi Pertiwi, an Indonesian construction and agricultural conglomerate, and how the LGZT small wheel loader has transformed their operations, setting a benchmark for success that resonates in both regions.

P.T. Established in 2005, Bumi Pertiwi has grown from a local agricultural support enterprise to a diversified enterprise engaged in housing construction, oil palm plantation management and infrastructure development throughout Indonesia. Operating in the densely populated islands of Java and the resource-rich regions of Sumatra, the company faced a major challenge: its existing fleet of aging equipment was struggling to cope with the growing demands of projects, especially in terms of efficiency and reliability. “We were using outdated forklifts that required constant maintenance, resulting in costly downtime,” explains Mr. Agus Santoso, PT's Director of Operations. Bumi Pertiwi. “Our teams in both construction and agriculture needed a solution that could handle a variety of tasks—from moving construction waste to loading palm fruit—without sacrificing productivity. That’s when we started looking for a compact wheel loader that could adapt to our different working conditions.”

The search for the right equipment led Mr. Santoso and his team to explore many options on the market. The climate of Southeast Asia, characterized by high humidity, heavy rainfall and dusty work sites, as well as the unique topography of South Africa, where many of PT's partner companies operate. Bumi Pertiwi, had special requirements. The equipment had to be corrosion-resistant, have good grip on uneven surfaces and be easy to maintain using local parts. “We looked at several international brands, but many of their offerings were either too large for our plantations or did not have the required strength for the rocky landscapes of South Africa,” Mr Santoso recalls. “We then came across a small LGZT wheel loader for sale and after reviewing the specifications and feedback from customers in neighboring countries such as Malaysia and Thailand, we decided to request a demo.”

LGZT's regional team in Southeast Asia responded quickly by organizing a demonstration of its flagship small wheel loader at the PT oil palm plantation. Bumi Pertiwi in Riau Province, Sumatra. The demonstration featured the LGZT ZL918 compact wheel loader, designed specifically for agricultural and light construction applications. “From the moment the machine arrived, we were impressed by its robust construction and user-friendly design,” says Ms. Siti Nurhayati, the plantation manager who led the demonstration. “Our workers, many of whom have limited experience with modern machinery, were able to operate a small wheel loader within an hour of training. What impressed us most was its maneuverability - it moved easily between palm trees, something our old loaders could never do. Additionally, fuel efficiency was remarkable; it used 30% less diesel than our existing equipment, which is a huge saving for us.”

After a successful demonstration, PT. Bumi Pertiwi has placed an order for 15 units of LGZT ZL918 small wheel loaders, 10 of which have been allocated for agricultural work and 5 for construction sites in Java. Delivery was completed within 45 days, which exceeded the company's expectations. “LGZT's logistics team coordinated flawlessly with our local partners to ensure the equipment was delivered on time and in perfect condition,” says Mr. Santoso. “They also provided on-site training to our entire team, covering operations, maintenance and troubleshooting. This level of after-sales support has been a key differentiator for us, especially compared to other brands that provide little to no post-purchase support.”

Impact of LGZT Small Wheel Loader on PT Operations. Bumi Pertiwi was immediate and drastic. In oil palm plantations, the compact wheel loader has revolutionized the harvesting process. Previously, workers had to manually collect palm fruits and transport them to collection points, a labor-intensive and time-consuming task. Using the LGZT compact wheel loader, the team can now load up to 5 tons of fruit in one trip, reducing the time required to harvest a hectare of plantation by 50%. “We used to need 10 workers per hectare to harvest the fruit; Now, with one compact wheel loader and two workers, we can get the job done in half the time,” explains Ms Nurhayati. “This allowed us to reallocate labor to other important tasks such as pruning and fertilising, increasing overall plantation productivity by 35% in the first three months.”

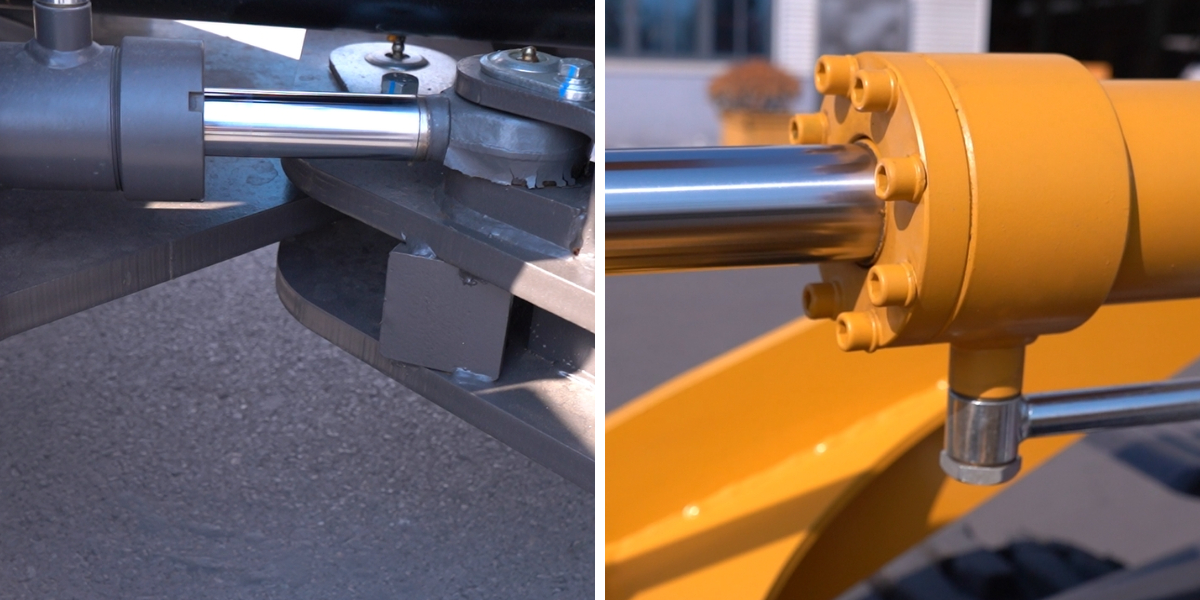

In the construction sector, the LGZT compact wheel loader has proven equally valuable. P.T. Bumi Pertiwi worked on a housing project in Bandung, West Java, where space was limited and the terrain was hilly. The compact wheel loader's tight turning radius and powerful hydraulics make it ideal for moving construction materials such as sand, gravel and cement to higher levels of the site. “Our previous forklifts were too bulky to navigate the narrow passages between construction buildings,” says Mr Joko Widodo, site manager. “The LGZT small wheel loader easily gets into tight spaces, and its 1.8 tonne lifting capacity allows it to handle most of our material handling tasks. We have also seen a significant reduction in maintenance costs - machines have been running for over 6 months with just a routine oil change, whereas our older loaders required major overhauls every 2-3 months.”

Success of the LGZT small wheel loader at PT. Bumi Pertiwi soon attracted the attention of the company's partners in South Africa. One of these partners, Green Acres Farms, a leading citrus producer in the Eastern Cape, faced similar problems due to outdated machinery. “We learned about the results that PT has achieved. Bumi Pertiwi with LGZT equipment, so we approached LGZT's South African distributor to inquire about selling a small wheel loader,” says Mr Thabo Mkhize, CEO of Green Acres Farms. “The South African citrus industry needs machinery that can handle heavy loads during harvest while remaining gentle enough to avoid damaging trees and fruit. The LGZT compact wheel loader seemed like the perfect fit.”

The South African LGZT team staged a demonstration at Green Acres Farms, showing the same ZL918 model that has proven successful in Indonesia. The demonstration took place at the height of the citrus harvest season, allowing Mr Mkhize and his team to test the small wheel loader in real-world conditions. “We were particularly impressed with the machine’s adjustable bucket, which can be modified to handle different types of fruit without damaging them,” says Mr Mkhize. “The loader tires are also designed to handle rough terrain, which is critical for our farms as many of our fields are located on slopes. After testing the machine for two weeks, we ordered 8 units and have never regretted it since.”

For Green Acres Farms, the small LGZT wheel loader has become an indispensable tool in their daily work. During harvest season, forklifts are used to transport citrus fruit from the fields to the packing plant, a task that previously required a fleet of trucks and additional labor. “Using the small LGZT wheel loader, we can transport fruit directly from the trees to the packaging line, reducing the number of processing steps and minimizing the risk of damage,” explains Mr Mkhize. “This has improved the quality of our products as more of our fruit reaches the market in perfect condition. Additionally, the truck's fuel efficiency has helped us reduce operating costs by 25%, which is a significant saving in a highly competitive industry.”

Like PT. Both Bumi Pertiwi and Green Acres Farms highlight LGZT's commitment to personalized service as a key factor in their satisfaction. LGZT worked closely with both companies to tailor the small wheel loader to their specific needs, including resizing the bucket for different types of crops and adding corrosion-resistant components so it could withstand the humid climate of Southeast Asia and the dry, dusty conditions of South Africa. “LGZT didn't just sell us a car; they provided a solution tailored to our unique challenges,” says Mr. Santoso. “When we mentioned that our employees wanted a simpler management system, they adjusted the interface to make it more intuitive. This level of customization is rare in the heavy equipment industry and is what sets LGZT apart from its competitors.”

PT success stories. Bumi Pertiwi and Green Acres Farms are not isolated cases. LGZT small wheel loaders have gained a strong reputation in both Southeast Asia and South Africa, and more and more companies are turning to the brand for their equipment needs. The company's focus on quality, durability and customer focus has made it a trusted partner to businesses in these regions where reliable equipment is critical to economic growth. “We have recommended LGZT small wheel loaders to several of our industry colleagues in Indonesia and South Africa,” says Mr. Santoso. “They were all impressed with the machine's performance and LGZT's support. It is clear that LGZT understands the unique needs of our markets and delivers products that exceed expectations.”

Looking ahead, LGZT plans to expand its product line in Southeast Asia and South Africa by introducing new compact wheel loader models with advanced features such as GPS tracking and remote monitoring. These features will allow customers to monitor the performance of their machines in real time, further increasing efficiency and reducing maintenance costs. “We are committed to continuous innovation and will continue to develop products to meet the changing needs of our customers in these regions,” says Mr. Li Gang, International Sales Director of LGZT. “The small wheel loader is just the beginning; We aim to become the leading brand for all heavy equipment needs in Southeast Asia and South Africa.”

For businesses in Southeast Asia and South Africa looking for a reliable, efficient and cost-effective small wheel loader, examples of successful PT projects. Bumi Pertiwi and Green Acres Farms provide strong evidence of LGZT's capabilities. Whether it's agricultural work such as loading palm fruit or citrus, or construction tasks such as material handling and site preparation, the LGZT small wheel loader delivers consistent performance, durability and value. “Investing in the LGZT small wheel loader was one of the best decisions we have made for our business,” says Mr Mkhize. “This has increased our productivity, reduced costs and given us a competitive advantage in the market. We look forward to continuing our partnership with LGZT for many years to come.”

In conclusion, the LGZT compact wheel loader has been a breakthrough for enterprises in Southeast Asia and South Africa, allowing them to overcome operational challenges and reach new heights of success. With a focus on quality, customization and after-sales support, LGZT is well positioned to continue to lead the market in these regions, helping businesses grow and prosper in an increasingly competitive environment. For those looking for a compact wheel loader that delivers performance and reliability, LGZT is a brand you can trust.