Front loader 2 tons

Front loader LG939F

Powerful engine:YUNNET YN38CBF4 engine provides high power and stable operation under heavy loads.

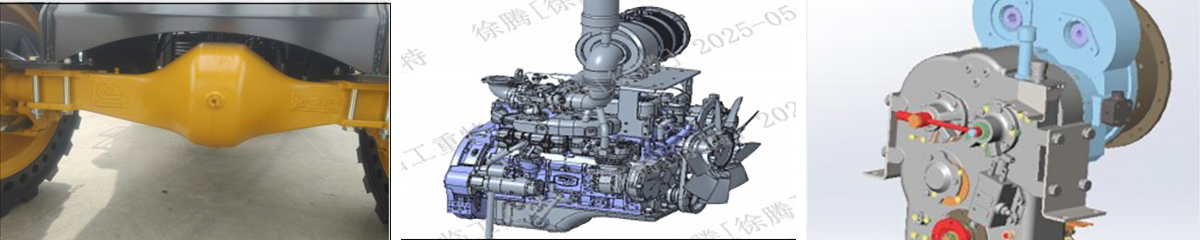

Good cross-country ability and load capacity:The reinforced axle and 16/70-24 tires ensure stable operation on difficult terrain and soft ground.

Reliable transmission:The 280 type gearbox is easy to maintain, reduces costs and provides efficient power transmission.

Operator comfort:A spacious cabin with good visibility, a pneumatic seat and a convenient handbrake increase comfort when working.

Front loader LG939F

The front loader LG939F is a strong and reliable model with a lifting capacity of 2 tons, designed to work at construction sites of medium scale, in agriculture and logistics. It is ideal for moving building materials, aligning the soil and performing general loading and unloading. Thanks to a strong design and a stable power system, this loader combines high carrying capacity and excellent maneuverability, which makes it an excellent choice for tasks that require both strength and accuracy. In addition, the possibility of light installation of attachments turns it into a multifunctional work machine, providing a greater return on investment.

What really distinguishes the front loader LG939F is its smart design, designed for durable operation. It is designed for long -term work with minimal maintenance costs, which helps to save time and reduce operating costs. Regardless of whether you work with heavy loads or in a limited space, this 2-ton loader provides stable performance and reliable operation. This is an ideal combination of efficiency, versatility and economic feasibility for real working conditions.

Product advantages:

1. Convenient service:

The large side door of the hood facies daily check, maintenance and repair of the engine and other components, which can reduce the repair time and increase the equipment use factor.

2. Stable hydraulic system:

The rear hydraulic tank helps optimize the distribution of the center of gravity and improve the stability of the entire machine, as well as facilitating hydraulic system maintenance and reducing the risk of hydraulic oil leakage.

3. High level of intelligence:

The CAN communication instrument panel can monitor the forklift's operating parameters in real time, such as engine speed, oil temperature, oil pressure, power and others, and also has the function of fault diagnosis, which can identify and solve problems in a timely manner, facilitating maintenance.

4. High adaptability to the environment:

The optional air conditioning system with cooling and heating functions creates comfortable conditions for the driver in any weather, keeping him in working condition and increasing work efficiency.

Specifications:

Engine:

(1) Equipped with YCD4J22T-115 engine, with a power of 85 kW and a torque of 390 N m. This engine provides enough power to handle all kinds of heavy-duty operations, allowing the forklift to cope well with loading, unloading, transportation and other tasks.

(2) Turbocharging improves air delivery efficiency, allowing for more complete air-fuel mixing and powerful combustion to maintain consistent power even in plateau or harsh environments.

Transmission:

(1) The use of 280 series split gearbox and optimal gear ratio effectively transmits power, improves the traction performance and acceleration qualities of the loader.

(2) The 280 series split gearbox is convenient for maintenance, reducing the cost and complexity of maintenance; the gear ratio is rationally selected, which can achieve high-efficiency operation and stable control.

(3) The reinforced drive axle with wheel reduction gears has a high load-bearing capacity and can be adapted to difficult operating conditions.

(4) 16/70-24 tyres with a large contact area provide good traction and cross-country ability both on rough construction site terrain and on soft soils.

It is capable of moving stably both on rough construction sites and on soft ground.

Performance Specifications

| Parameter | Meaning | Parameter | Meaning |

|---|---|---|---|

| Minimum turning radius (mm) (outer edge of right front wheel) | 6060 | Bucket width/depth (mm) | 2235/565 |

| Theoretical slope ability (°) | 25 | Wheelbase (mm) | 2850 |

| Maximum speed (km/h) | 33 | Bucket lifting time without load (s) | 5.8 |

| Minimum speed limit (km/h) | 6 | Bucket lowering time without load (s) | 3.94 |

| Maximum unloading height (mm) | 3600 | Unloading time without load (s) | 1 |

| Unloading distance (mm) | 600 | Total cycle time (s) | 10.74 |

| Unloading angle (°) (theoretical value) | 35 | Maximum lifting force (kN) | 51 |

| Bucket capacity (m³) | 1.1 | Maximum traction force (kN) | 48 |

Dimensions and weight parameters

| Parameter | Meaning | Parameter | Meaning |

|---|---|---|---|

| Length (mm) | 7060 | Ground clearance (mm) | 350 |

| Height (mm) | 2950 | Wheelbase (mm) | 1650 |

| Width (mm) | 2230 | ||

| Weight | |||

| Rated load capacity (kg) | 2000 | ||

| Gross vehicle weight (without operator) (kg) | 6025 |

Engine

| Parameter | Meaning | Parameter | Meaning |

|---|---|---|---|

| Model | YN38CBF4 | Number of cylinders | 4 |

| Manufacturer | Y u NN EI | Cylinder diameter/stroke (mm) | 102×115 |

| Nominal power (kW) | 85 | Minimum specific fuel consumption (g/kW h) | ≤205 |

| Nominal speed (rpm) | 2400 | Maximum torque (Nm) | 420 |

| Working volume (l) | 3.76 |

Transmission system

| Parameter | Meaning |

|---|---|

| Type | 280 split double height |

| Transmission | Front 4 / Rear 4 |

| Type of brakes | Air brakes |

| Here | With reinforced side of the big wheel |

| Tire type | 16/70-24 |

| Front tire pressure (MPa) | 0.33 |

| Pressure in the rear wheels (MPa) | 0.30 |

Steering system

| Parameter | Meaning |

|---|---|

| Type of system | Fully hydraulic steering |

| Rotation angle (°) | 33 |

| Working pressure (MPa) | 16 |

Tanks for refueling

| Parameter | Meaning | Parameter | Meaning |

|---|---|---|---|

| Fuel tank (l) / theoretical volume | 96 | Engine (l) | 11 |

| Hydraulic oil (l) / theoretical volume | 99 | Transmission (l) | 28 |

| Bridge (L) - Non | 14 | Brake system (l) | 3 |

Company strength:

The company LGZT founded in 2013 (Shandong Huawei Zot Machinery Co., Ltd.) is engaged in research, development, production, sale and maintenance of highly effective small -sized construction equipment. The company was awarded a number of national awards, including the status of a “small giant” in the category of specialized, accurate, unique and innovative enterprises, the status of a national high -tech enterprise, a brand of quality of Shandun province and a champion for the production of single goods.

Currently, the company offers six main food series: ZL, LG, W, WE, export models and all -terrain loaders - a total of more than 1000 varieties. Products are exported to more than 20 countries and regions, including Russia, Australia and Vietnam.

The company strives for continuous production of reliable equipment and the provision of attentive and high -quality service, helping global customers to create great value. LGZT was the first in China to use the processes of the automotive industry in the production of small -sized special equipment. Equipped with the most modern lines of electrophoretic capsuits and powder coloring in China, the company conducted an environmentally friendly transformation: from traditional oil and water -soluble colors, it passed to the powder coating. This completely eliminated the Voc pollution problem, and also solved the issues of corrosion and fading of small -sized construction equipment.