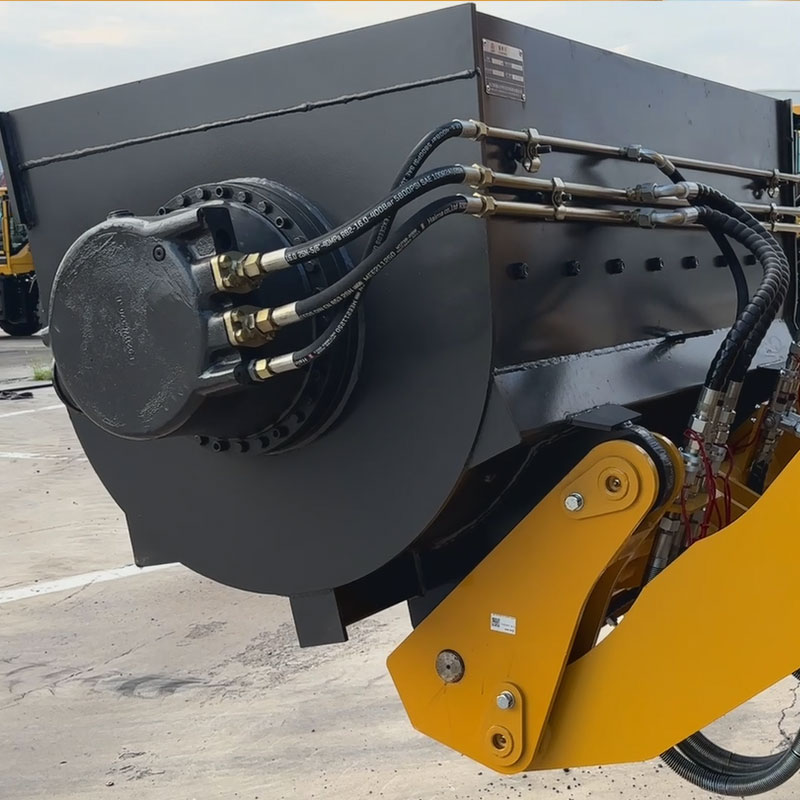

Mixing bucket

1. Uniform mixing of materials

2. Hydraulic drive

3. Easy to install

4. Original production at the factory in China

5. Search for agents

With the trend towards miniaturization and multifunctionality of construction equipment, mixing buckets are becoming the main auxiliary tool for increasing the efficiency of small wheel loaders.

What is a mixing bucket?

A mixing bucket is a hydraulic mixing container built into the end of a loader's boom and using integrated auger blades to mix materials. It can be quickly installed on small wheel loaders for on-site mixing and transport of materials such as concrete and fertilizer.

Equipped with a mixing bucket, a small wheel loader can independently mix and pour concrete. This single machine can replace a concrete mixer truck and concrete pump, reducing construction costs on small construction sites by 30%.

LGZT small loaders equipped with mixing buckets feature large loading capacity, high power and stable operation. The mixing bucket is made of wear-resistant steel, which ensures long service life. We are recruiting agents all over the world.

Company advantages:

Founded in 2013, the companyLGZTis engaged in the research, development, production, sales and service of high-performance small-sized construction equipment. The company has been awarded a number of prestigious awards, including the national Small Giant status of "Specialized, Fine, Unique and Innovative", the title of National High-tech Enterprise, and also recognized as Shandong Province Quality Brand and Shandong Province Single Product Champion.

Today, LGZT offers six main product series: ZL, LG, W, WE, export-oriented series and off-road forkloaders, - more than 1000 models in total. Products are exported to more than 20 countries and regions, including Russia, Australia and Vietnam.

The company is committed to continually producing reliable products and providing attentive, quality service, helping customers around the world create added value. LGZT was the first in the country to introduce automotive technology into the production of small-sized construction equipment. Equipped with China's most advanced electrophoretic shot blasting and powder coating lines, the company has successfully undergone an environmental transformation from traditional oil-based and water-based paints to powder coating. This completely solved the problem of VOC (volatile organic compound) pollution, and also eliminated disadvantages such as rusting and fading of equipment.