One machine, double capabilities, creating the future: LGZT Bucket Mixer Loader is changing the ecosystem of small infrastructure projects

Introduction: Construction site "transformers" are changing the logic of construction

At a new rural highway construction site in Shanxi Province, a pilot loader equipped with a concrete mixing bucket moves quickly: the front bucket rotates to mix materials, then pivots to precisely pour the finished concrete into road pavement forms. This "production-on-the-go" scenario is becoming the new norm for small infrastructure projects.

I. Technological innovation: when forklifts are equipped with "smart hearts"

A Revolutionary Breakthrough in Functional Integration

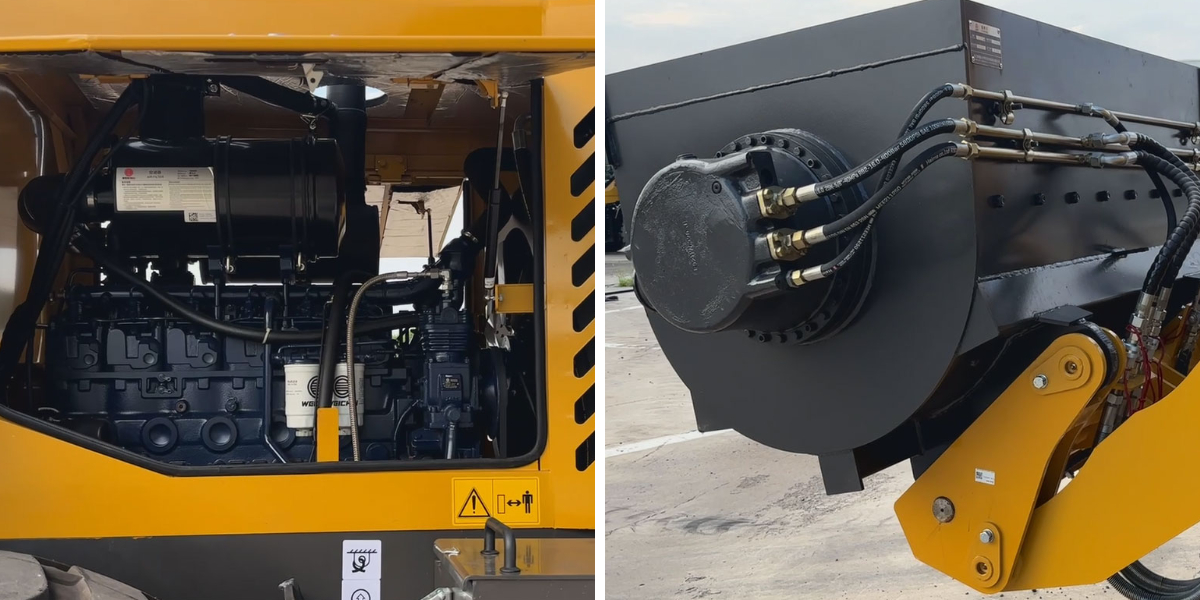

The quick shift system allows you to switch roles: using a patented fast shift device, LGZT loader can complete the switching of a mixing bucket and a standard bucket within 10 minutes. The dismantling of the mixing system restores the traditional loading function, while the installation of the mixing cylinder converts it into a movable concrete production line, completely violating the functional boundaries of the equipment.

Hydraulic intellectual joint control: using a two -ane hydraulic technology of a combined flow, it not only provides walking, but also drives moving blades for rotation in both directions, which allows you to produce three -dimensional mixing of sand, gravel and cement. Homogeneity is significantly improved in comparison with traditional equipment.

2. Improving the adaptability of the scene

Accurate functioning in closed spaces: the design of the articulated body provides an extremely small radius of the rotation of the equipment, allowing it to turn freely in limited spaces, such as tunnels and repair of the courtyard. The environmental system automatically reveals obstacles to avoid the danger of a collision. Construction without electricity: a hydraulic drive replaces the electric system, solving the problem of electricity deficiency at the field construction sites. It is especially suitable for scripts such as preserving water resources in remote areas and the maintenance of mountain roads.

II. Regulation in the field of human rights scenarios: "Complex Warrior" for small infrastructure projects

1. Field for utilities

Effective repair of the road with a closed contour: one device simultaneously completes the entire process of loading crushed materials from the old road surface, mixing new concrete and hospital. Compared to the traditional mode “Excavator + Mixer Truck + Manual Management”, it reduces the mechanical configuration by 60% and significantly reduces traffic control time. Thematic study: in 2024, as part of the reconstruction project of the City Pipeline of the XI 'An Municipal Department, after the adoption of this equipment, the number of inspection wells repaired in one day increased by 40%, and the problem of dust caused by frequent entry and exit of concrete vehicles was also avoided.

2. Construction in order to restore rural areas

Optimizing rural house construction costs: When residents of one village in Yunnan build their own houses, they rent concrete mixers to produce concrete on-site, saving on transportation costs and waiting time for commercial concrete. The overall cost of building materials has been reduced by approximately 30%.

Application of micro-water protection projects: during the construction of terraced irrigation canals, equipment for mixing materials and pouring was moved along the slope, which successfully solved the problem of large vehicles being unable to access steep slopes.

III. Human Rights Situation Transforming Industry: Creating a New Ecosystem for Construction Equipment

The production chain is currently being reconstructed.

Expanding after-sales service: Third-party modification companies have adopted the "mixed bucket rental + technical guidance" model, which allows users to carry out multi-functional construction without purchasing new machines and lowers the equipment investment threshold for small and medium-sized contractors.

Accelerated innovation support: Developing adjustable blades, wear-resistant bucket teeth, and other accessories based on the characteristics of different materials, allowing the same equipment to expand new functions such as mixing feed and mixing fire-resistant materials.

GLZT is currently recruiting cooperative agents worldwide. Contact us below.

Number of company employees:

LGZT was founded in 2013 and is engaged in research, development, production, sale and maintenance of inexpensive small construction equipment. The company was awarded the title of national "specialized, exquisite, unique and innovative" small giant enterprise, a national high -tech enterprise, a quality brand of the province of Shandun and the champion of Shandun province for the production of plain products. Currently, it offers six main series of products, including ZL, LG, W, WE, exported, and fork loaders of increased strength, with more than 1000 varieties in total. Products are exported to more than 20 countries and regions, including Russia, Australia and Vietnam.

The company is engaged in continuous production of reliable products and provides attentive and high -quality services to help global customers create great value. For the first time in the country, car production processes began to be applied to the production of small construction equipment. The company, equipped with the most advanced lines of electrophoretic fragrance processing and application of powder coatings, has achieved the transition from traditional oil and water colors to the processes of patch coatings, completely solving the problem of pollution of the elk and solving issues such as light drain and drying out of small construction equipment.