LG933F is a reliable 1.5-ton wheel loader created for small and medium-scale projects. Regardless of whether you work in construction, agriculture, utilities or engage in loading and unloading, this machine is compact, power and high efficiency. It is ideal for work in a limited space and quickly copes with such tasks as layouts of sites, loading or transportation of materials.

What is LG933F distinguish among analogues?

Its well -thought -out design combines lightweight assembly, control flexibility and low fuel consumption, while maintaining the simplicity of maintenance. Thanks to the modular system of attachments, this 1.5-ton loader easily adapts to various tasks: rapidly replaced buckets, pitchfork or brushes make it a universal solution for any projects.

![Front loader 1.5 tons Front loader 1.5 tons]()

Performance parameters:

| Indicators |

Meanings |

Indicators |

Values |

| Minimum turning radius (mm) |

5240 |

Bucket width (mm) |

2135 |

| Theoretical gradeability (°) |

25 |

Wheelbase (mm) |

2420 |

| Maximum speed (km/h) |

33 |

Cycle time for three operations (s) |

10.4 |

| Minimum speed limit (km/h) |

5 |

Maximum lifting force (kN) |

≥30 |

| Maximum unloading height (mm) |

3560 |

Bucket capacity (m³) |

0.87 |

| Unloading distance (mm) |

790 |

Combined operating mode (kN) |

- |

| Maximum traction force (kN) |

47 |

Bucket width (mm) |

27 |

Overall dimensions and weight parameters:

| Indicators |

Values |

Indicators |

Values |

| Length (mm) |

6350 |

Minimum ground clearance (mm) |

370 |

| Height (mm) |

2950 |

Wheelbase (mm) |

1560 |

| Width (mm) |

2135 |

|

|

| Weight characteristics |

Nominal lifting capacity (kg) |

1500 |

|

|

Gross vehicle weight (without operator, kg) |

5575 |

|

Engine:

| Options |

Values |

Options |

Values |

| Model |

YN38TRF4 |

Number of cylinders |

4 |

| Manufacturer |

Y u NN EI |

Cylinder diameter/stroke (mm) |

102×115 |

| Nominal power (kW) |

36.8 |

Specific fuel consumption (g/kW h) |

≤235 |

| Nominal speed (rpm) |

2400 |

Maximum torque (Nm) |

237 |

| Working volume (l) |

3.76 |

|

|

Transmission system:

| Options |

Values |

| Type |

265 split double height |

| Transmission |

4 front / 4 rear |

| Brake system type |

Pneumatic brakes |

| Bridge |

Central wheel reducer |

| Tire model |

16/70-20 |

| Front tire pressure (MPa) |

0.33 |

| Rear tire pressure (MPa) |

0.30 |

Steering system:

| Options |

Values |

| System type |

Fully hydraulic steering |

| Rotation angle (°) |

33 |

| Working pressure of the system (MPa) |

16 |

Capacity of fuel and working fluids:

| Options |

Values |

Options |

Values |

| Fuel tank (l) |

84 |

Engine system (l) |

6.8 |

| Hydraulic oil (l) |

84 |

Transmission (l) |

22 |

| Bridge (l) - single |

14 |

Brake system (l) |

1.5 |

Specifications

Engine

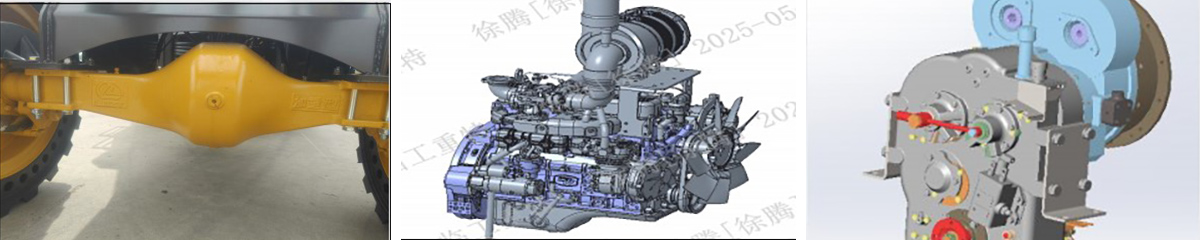

1. Equipped with Yunnei YN38GBZ engine with 76 kW power and 340 Nm torque, which provides high performance and significant power reserve to handle any heavy-duty work.

2. A high-efficiency turbocharger with fast response is used, ensuring optimal filling of the cylinders and complete combustion of fuel.

3. Peak torque is achieved in the range of 1200-1800 rpm, which reduces fuel consumption and makes it ideal for forklifts with frequent start-stop cycles and low-speed operation.

Transmission

1. The 265 split gearbox with optimally selected gear ratios ensures efficient power transmission, improving the traction and dynamic characteristics of the loader.

2. The 265 split gearbox with fixed axles and hydraulic shifting (4 forward/reverse gears) is easy to operate and shifts smoothly, reducing operating costs.

3. Specially designed wheel reducers significantly increase the lifting capacity, allowing operation with heavy loads in difficult conditions.

4. 16/70-20 tires provide:

Maximum contact area with the surface

Excellent grip

High cross-country ability

Stable operation on all types of surfaces

![Front loader 1.5 tons Front loader 1.5 tons]()

![Front loader 1.5 tons Front loader 1.5 tons]()

Comfort characteristics:

1. The cab is designed with ergonomics in mind, with spacious interior space and wide visibility, which effectively reduces the driver's blind spot and reduces fatigue during operation.

2. The air suspension seat automatically adjusts according to the driver's weight and road conditions, providing a good shock-absorbing effect. This reduces the impact of road irregularities on the driver's body, reducing fatigue during long-term use.

3. The cabin has high tightness, effective dust protection and noise insulation, which increases working comfort, reduces the impact of the external environment and improves control safety.

4. The optional climatic system with heating and cooling creates comfortable working conditions for the driver. Regardless of whether the hot summer or cold winter, it supports the optimal condition of the driver, increasing the performance and comfort of labor.

![Front loader 1.5 tons Front loader 1.5 tons]()

The advantages of the company:

Founded in 2013, LGZT is engaged in research, development, production, sale and maintenance of highly effective small -sized construction equipment. The company was awarded a number of prestigious awards, including the status of a national “small giant” in the category “specialized, subtle, unique and innovative”, the title of national high -tech enterprise, and was also recognized as a high -quality brand of Shandun province and the production champion of one product in the province of Shandun.

To date, LGZT offers six main series of products: ZL, LG, W, WE, an export-oriented series and off-road fork loaders-only more than 1000 models. Products are exported to more than 20 countries and regions, including Russia, Australia and Vietnam.

The company strives for the constant production of reliable products and the provision of attentive, quality service, helping customers around the world to create additional value. LGZT was the first in the country to introduce automotive technology into the production of small -sized construction equipment. Equipped with the most advanced in China lines of electrophoretic shot -toestrian processing and powder staining, the company has successfully passed the environmental transformation: from the use of traditional oil and water -based paints - to powder coloring. This completely solved the problem of pollution of the moos (volatile organic compounds), and also eliminated such disadvantages as rusting and fading of the technique.

![Front loader 1.5 tons Front loader 1.5 tons]()