Mixing bucket loader

Adaptation to a complex environment

Efficiency and practicality

Environmental protection and safety

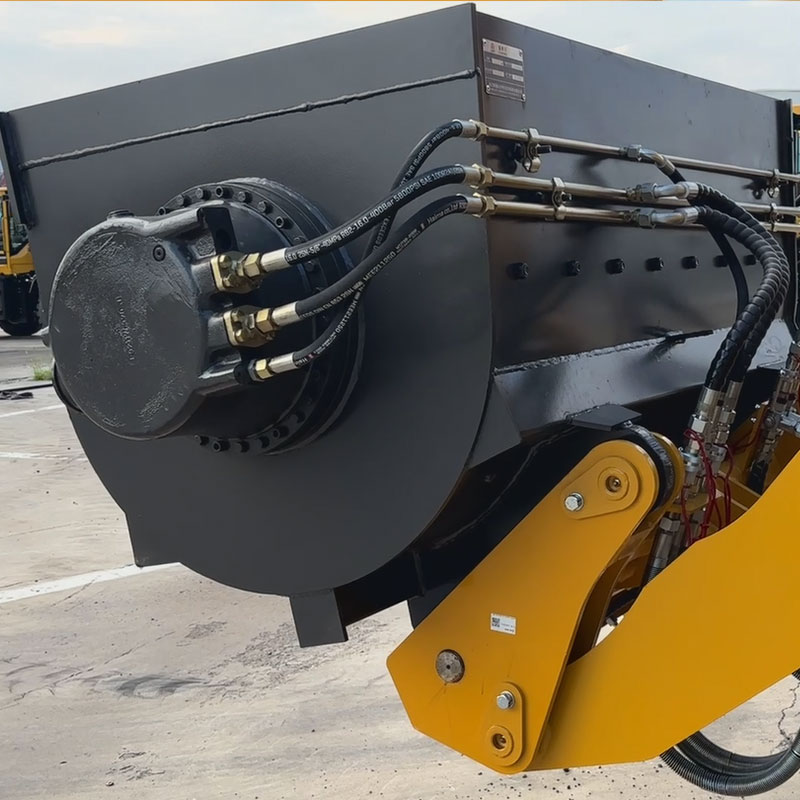

Concrete mixing bucket is a new type of engineering machinery that integrates the mobile loading and unloading functions of the forklift and the mixing functions of the forced concrete mixer. It is designed for concrete construction scenes and solves the pain points of "coordination of multiple equipment, dependence on power supply and low efficiency" in traditional construction.

Core Functions and Values

It combines “loading-mixing-transfer-unloading” in one device, replacing the combined mode “Loading loader + mixing mixer + movement of a vehicle” in traditional construction. By replacing the components of the bucket and the mixing cylinder, it can be used as a loader for loading and unloading materials, and can also be converted into a mixer for mixing concrete, truly realizing the “one machine for multi-purpose”, significantly reducing the amount of equipment on the construction site and reducing the costs of the purchase of equipment, maintenance and labor (for example, excluding the cost of equipment such as transportation Self -seats and concrete mixers, and reducing the number of workers). The main advantages

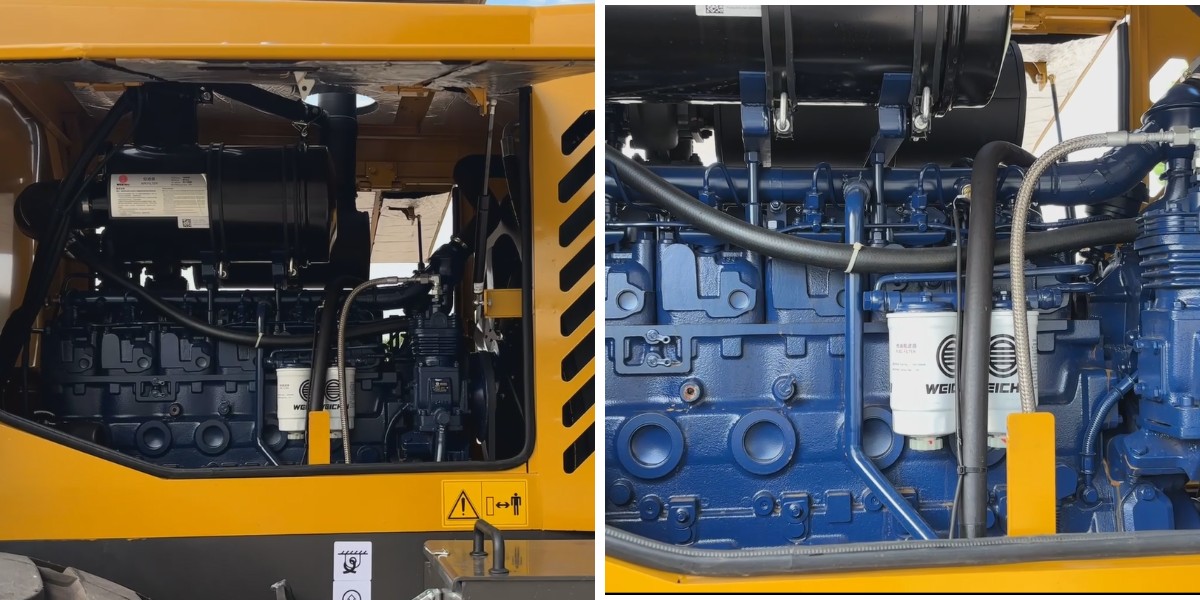

1. Adapt to complex conditions: With the hydraulic transmission system of the loader for mixing control, no external power source is required, which perfectly solves the construction needs in places with inconvenient power supply such as wild, mountainous areas and small sites (such as new rural construction, rural road strengthening, mountain infrastructure, etc.).

2. Efficient and practical: Bidirectional mixing blades are adopted to ensure uniform mixing of concrete; fully enclosed gear reducer prevents sand from entering and reduces the frequency of maintenance; hydraulic drive makes the operation flexible, mixing time is short and efficient.

3. Environmental protection and safety: Integrated operation shortens the transportation links of materials and reduces dust and noise pollution; at the same time, the equipment has a compact structure and simplified operation procedures, which reduces safety risks during on-site work.

Applicable scenarios

Particularly suitable for small to medium-sized concrete projects such as self-built rural homes, rural roads, small water projects and areas with difficult road conditions. It can effectively solve the problems of "small site, lack of electricity and complex transportation", helping construction organizations reduce costs and improve efficiency.